19

2024-01

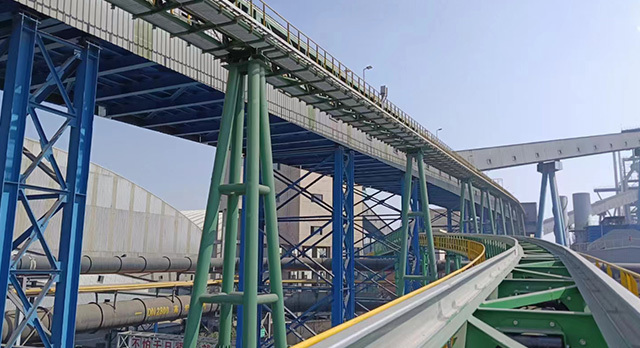

Should the Truss Support of Retrofit Pipe Belt Machine Borrow the Existing Buildings

If it is really impossible to do the foundation on the ground, you can consider using the existing plant roof, the existing belt gallery support, pipe gallery support, transfer station, etc., but to borrow these structures to do the pipe belt machine support point, generally need to carry out structural accounting of its force load. Many old buildings because of the long time, the owner generally can not provide the structure and foundation construction drawings of the building, the force accounting will be very different, in this case need accounting can not borrow as far as possible.

2024-01-19

19

2024-01

Design Points and Application of Belt Conveyor in Large Port

With the development of the national economy, the volume of bulk dry bulk cargo such as coal, ore, sand, bulk grain, fertilizer, etc. in water transportation is increasing year by year, and the tonnage of transport ships is becoming larger and larger, so the loading and unloading equipment is also developing in the direction of large, efficient and low energy consumption. Port transport machinery plays a key role in the specialized terminal of bulk cargo, and belt conveyor, as one of the important components of port transport machinery, lays the foundation for the reliable, efficient, energy-saving and economic operation of port transport machinery. Combined with the process requirements and characteristics of port transportation machinery, the design points of port belt conveyor are highlighted and the application situation is briefly listed.

2024-01-19

19

2024-01

Daily Operation Procedures and Maintenance of Belt Conveyor

First, the belt conveyor operating procedures: 1 before the operation of the operating procedures (1) whether the belt conveyor on a solid basis, and the lubrication point of the oil is sufficient. (2) Whether the tightness of the conveyor belt is appropriate, whether the transmission parts such as bearings and gears are intact, whether the safety protection devices are safe, reliable and complete, and whether the equipment grounding treatment is good. (3) Before the conveyor officially starts to work, it should run in the air first, and the time should be controlled within 3-5 minutes. During this period, it should be checked whether there is any abnormal phenomenon in the motor and rotating part, whether the idler rotates flexibly, and whether the conveyor belt slips or deviates.

2024-01-19

19

2024-01

Comparative Analysis of the Cost of Pipe Belt Conver and Fully Enclosed Corridor Belt Conver

Material transportation. Powdery materials such as lime, dedusting ash, desulfurization ash and fly ash shall be transported in a closed manner by means of tubular belt conveyor, pneumatic conveying equipment and tanker. Iron concentrate, coal, coke, sinter, pellet, limestone, dolomite, ferroalloy, blast furnace slag, steel slag, desulfurization gypsum and other lumpy or sticky wet materials shall be transported in a closed manner by tubular belt conveyor or belt corridor; if it is really necessary to transport by automobile, it shall be transported in a closed carriage or covered tightly, and dust suppression measures such as humidification shall be taken during loading and unloading. Material conveying and blanking points shall be equipped with gas collecting hood and dust removal facilities, or dust suppression measures such as spray shall be taken. Wheel and body washing facilities shall be provided at the stock yard exit. The roads in the plant area shall be hardened, and cleaning, watering and other measures shall be taken to keep them clean.

2024-01-19

28

2020-03

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-15190313883 86-18762809313

E-mail: sales@hdconveyor.com

Official Website