On April 28, 2019, the Ministry of Ecology and Environment and other five departments jointly issued the Opinions on Promoting the Implementation of Ultra-low Emissions in the Steel Industry. The summary of the opinions on material transportation:

2. Material transportation. Powdery materials such as lime, dedusting ash, desulfurization ash and fly ash shall be transported in a closed manner by means of tubular belt conveyor, pneumatic conveying equipment and tanker. Iron concentrate, coal, coke, sinter, pellet, limestone, dolomite, ferroalloy, blast furnace slag, steel slag, desulfurization gypsum and other lumpy or sticky wet materials shall be transported in a closed manner by tubular belt conveyor or belt corridor; if it is really necessary to transport by automobile, it shall be transported in a closed carriage or covered tightly, and dust suppression measures such as humidification shall be taken during loading and unloading. Material conveying and blanking points shall be equipped with gas collecting hood and dust removal facilities, or dust suppression measures such as spray shall be taken. Wheel and body washing facilities shall be provided at the stock yard exit. The roads in the plant area shall be hardened, and cleaning, watering and other measures shall be taken to keep them clean.

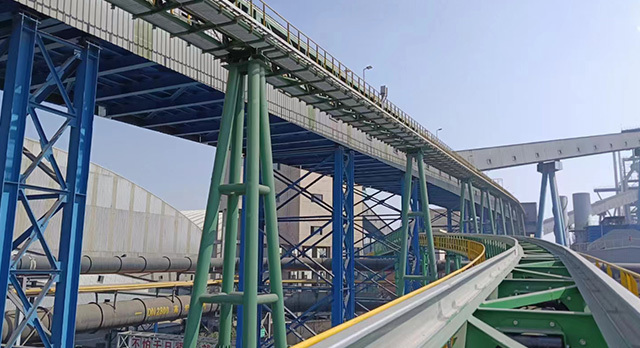

The conveying of non-powdery materials strictly requires the use of pipe belt conveyor or fully sealed belt corridor. The weight and cost of these two kinds of conveying forms are compared and analyzed as follows, which can be used as reference for design-related decision-making.

1. Comparison Condition Description

1. Conveying materials: coal, specific gravity 0.85, transportation capacity 250 t/h, block size below 80mm, normal temperature;

2. The belt speed of the pipe belt machine is 2.5mm, and the pipe diameter is 250mm; the belt speed of the groove belt conveyor is 1.6mm, and the bandwidth is 800mm;

3. The pipe belt conveyor and the belt conveyor take the walkways on both sides, and the width of the walkways is 800mm;

4. Pipe belt conveyor and belt conveyor are of overhead structure with a uniform span of 24m;

5. The spacing between the upper and lower idlers of the straight section of the pipe belt conveyor is 1.6m, the spacing between the upper idlers of the belt conveyor is 1.2m, and the spacing between the lower idlers is 3 m;

6. The total length of the conveyor shall be 200 meters, considering the selection and driving part of the belt. The power of the groove belt is 37kw, and the power of the tube belt conveyor is 75kw;

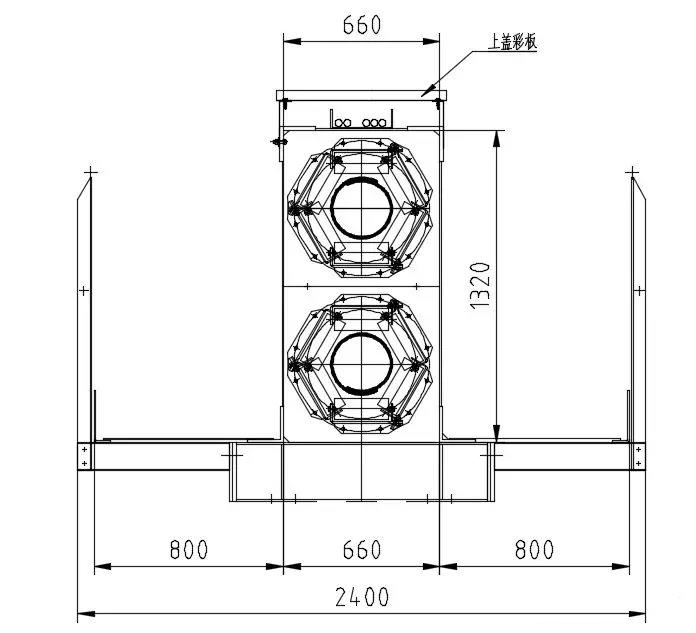

7. The truss structure of pipe belt conveyor is as follows:

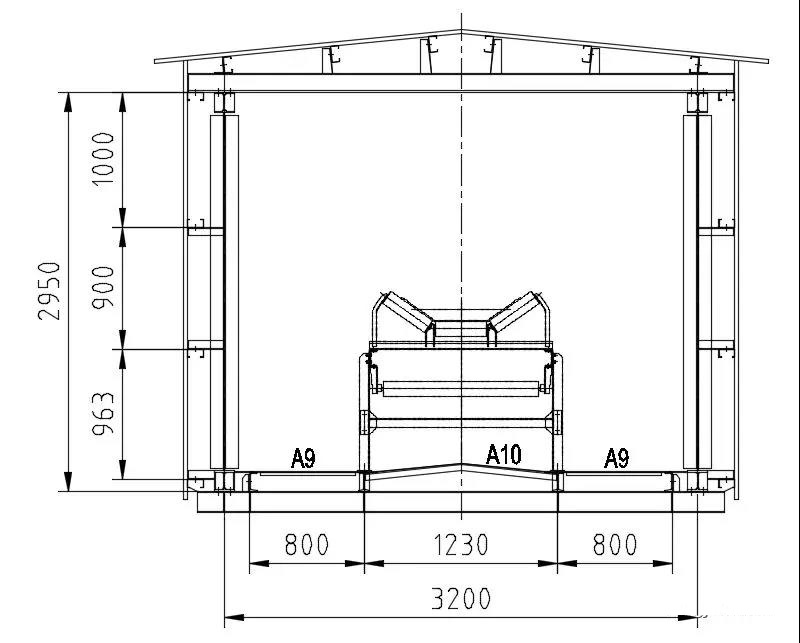

8. The truss structure of the fully enclosed belt conveyor is as follows:

9. The cost comparison does not consider the supporting column and the head and tail driving parts for the time being, and only compares the structure of the 24-meter truss with the closed, belt and idler;

2. Weight Comparison Summary

1. Model weight comparison of bearing idler

| |

Roller model |

Number of idlers |

Roller single weight kg |

Total weight of roller kg |

Single weight of bracket kg |

Total weight of bracket kg |

| Belt conveyor |

89x315 |

60 |

3.59 |

215.4 |

11.32 |

226.4 |

| Pipe belt machine |

89x230 |

90 |

2.75 |

247.5 |

2 |

180 |

1) The belt conveyor bearing roller is a standard three roller with a groove angle of 35 degrees;

2) The bearing roller of the pipe belt conveyor is in the form of hexagonal double-sided arrangement;

2. Comparison of return roller model weight

| |

Roller model |

Number of idlers |

Roller single weight kg |

Total weight of roller kg |

Single weight of bracket kg |

Total weight of bracket kg |

| Belt conveyor |

89x950 |

8 |

9.73 |

77.84 |

3.77 |

30.16 |

| Pipe belt machine |

89x230 |

90 |

2.75 |

247.5 |

2 |

180 |

1) The return idler of belt conveyor is a standard parallel lower idler;

2) The return roller of the pipe belt conveyor is of hexagonal double-sided arrangement;

3. Weight comparison of leg structural parts of middle frame

| |

Weight of intermediate frame kg |

Leg IQuantity |

Leg IIQuantity |

Total weight of leg kg |

Total weight of structure kg |

| Belt conveyor |

358 |

4 |

4 |

133 |

491 |

| Pipe belt machine |

0 |

0 |

0 |

0 |

0 |

1) The middle frame and legs are selected according to light and medium standards;

2) H value of leg shall be selected according to the 800;

4. Weight comparison of adhesive tape models

| |

Tape type |

Tape single weight kg |

Weight of adhesive tape kg |

| Belt conveyor |

B800-EP100/4(4.5 1.5) |

9.376 |

450 |

| Pipe belt machine |

B1000-GEP200/4(5 3) |

14.8 |

710.4 |

5. Weight comparison of truss structure

| |

Truss section size |

Weight of truss structure kg |

walkway t6diamond plate kg |

Truss closure weight kg |

Total truss weight kg |

| Belt conveyor |

3200x2950 |

6800 |

3200 |

3690 |

13690 |

| Pipe belt machine |

660x1320 |

6000 |

1810 |

330 |

8140 |

1) The cross-sectional form of the belt conveyor corridor is shown in the figure below. The walkway plate includes the sealing plate at the bottom of the truss, and the closed part of the truss includes the closed purlins and color steel plates on the side and top, excluding the window part;

2) The cross-sectional dimensions of the truss of the pipe belt conveyor are shown in the following figure. The truss structure includes the truss body, walkways and railings. Considering that the pipe belt conveyor does not have return spreading materials, only the walkways on both sides are included, and the truss closed part only includes the rainproof color plate and fixing frame above the truss of the pipe belt conveyor.

6. Weight summary comparison

| |

Roller weight |

Roller support weight |

Weight of middle frame leg |

Tape Weight |

truss weight |

Weight Summary |

| Belt conveyor |

293 |

256 |

491 |

450 |

13690 |

15180 |

| Pipe belt machine |

495 |

360 |

0 |

710 |

8140 |

9705 |

7. Weight comparison summary:

1) The body part of the two does not include the adhesive tape and truss structure. The total weight of the belt conveyor is 293 256 491=1040kg, the total weight of the pipe conveyor is 495 360=855kg, and the belt conveyor is about 20% heavier than the pipe conveyor;

2) The main body contains adhesive tape, belt conveyor 1 040 450=1490kg, pipe belt conveyor 855 710=1565kg, and the pipe belt conveyor is about 5% heavier than the belt conveyor;

3) The biggest difference between the two weights lies in the truss part, and the weight of the closed corridor of the belt conveyor is basically 1.7 times the weight of the truss of the pipe belt conveyor;

4) The weight of the two trusses is much larger than the weight of the equipment body. After all the weights are summarized, the total weight of the belt conveyor is about 1.6 times of the total weight of the pipe belt conveyor.

5) If the closure is not considered, the weight of the belt conveyor truss and the pipe belt conveyor truss is basically the same.

3. cost comparison summary

| |

Roller price |

Roller support price |

Middle frame leg |

Tape Price |

Truss price |

Price Summary |

| Belt conveyor |

3520 |

2560 |

4910 |

7680 |

136900 |

155570 |

| Pipe belt machine |

5940 |

3600 |

0 |

17040 |

81400 |

107980 |

1. Price Description:

1) The roller price is estimated by 12 yuan/kg;

2) The idler support and other structural parts are estimated at 10 yuan/kg;

3)B800 groove tape is estimated by 160 yuan/m; B1000 tubular tape is estimated by 355 yuan/m;

4) The price of truss is estimated by 10 yuan/kg;

2. Price comparison summary:

1) Summarize the main body parts of belt conveyor such as idler, idler support, middle frame and supporting leg, and adhesive tape. The cost of belt conveyor is 3520 2560 4910 7680=16370 yuan, the cost of pipe belt conveyor is 5940 3600 17040=26580 yuan, and the cost of pipe belt conveyor is 1.6 times that of belt conveyor.

2) According to the fully enclosed summary of environmental protection requirements, the cost of belt conveyor is 155570 yuan, the cost of pipe belt conveyor is 107980 yuan, and the cost of belt conveyor is 1.44 times that of pipe belt conveyor.

4. Conclusion

1. Compared with the overhead full-pass closed corridor belt conveyor and the overhead pipe belt conveyor, the weight of the belt conveyor is about 1.6 times of the weight of the pipe belt conveyor, the cost of the belt conveyor is about 1.44 times of the cost of the pipe belt conveyor, and the investment cost performance of the pipe belt conveyor is better than that of the closed corridor belt conveyor.

2, closed corridor belt conveyor if you need to reduce costs, you can start from the corridor structure, the specific summary of the next issue to share the "tube belt conveyor and fully closed corridor belt conveyor cost comparative analysis (II)."