17

2018-05

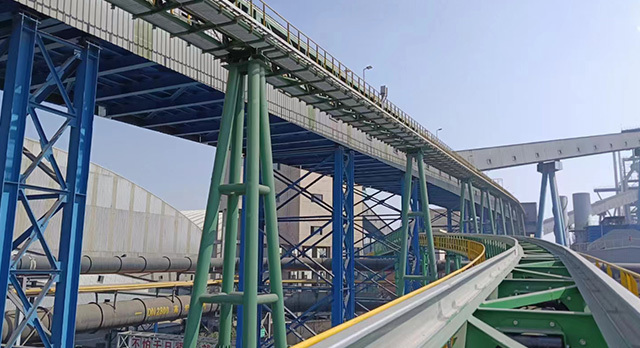

How to improve the service life of the conveyor belt

Electromechanical Online News] In recent years, as the demand for coal in European and American countries has plummeted, my country's southern region has abundant rain this year, and major hydropower stations are operating at full capacity. At the same time, energy conservation and emission reduction have become the top priority of enterprises and even the country. It has become the reason for the decline in coal prices this year. The drop in coal prices has greatly affected the enthusiasm of upstream related enterprises to put into production, and it is particularly important to improve the recycling of resources within the enterprise. If you don't say far away, take the conveyor belt as an example. I believe it is a big expense for every coal mining enterprise. When it comes to this, I would like to briefly talk about some problems about improving the conveyor belt and some about improving the conveying.

2018-05-17

17

2018-05

Selection and Function of Roller Conveyor

The roller conveyor mainly relies on the arrangement of the rollers to form a complete conveyor line. It can not only transport materials separately, but also combine with other conveying equipment to form a complex conveying system. The main components of the conveying equipment in the drive roller, it is to rely on the friction between the conveyor belt to drive the conveyor belt to run. The drive roller in the roller conveyor can be divided into light, medium and heavy according to the size of its bearing capacity, and the diameter of the same roller has several different shaft diameters and center spans for selection. 1, light roller: bearing aperture is usually 80-100mm, shaft and hub one

2018-05-17

17

2018-05

Analysis on Prevention and Treatment of Conveyor Belt Deviation

Conveyor belt deviation is a fault often encountered in the process of conveyor use, and it is also a headache for customers. How to prevent and eliminate the fault of the conveyor belt deviation? First check the cause, and then one by one "the right medicine". Preventive measures to 1. the deviation of the conveyor belt (1) improve the installation quality (2) improve the quality of the conveyor belt joint;(3) strengthen the inspection and maintenance of the tour (4) to ensure that the loading is not biased;(5) to ensure that the cleaning device is normal. On-site treatment method for 2. conveyor belt deviation (1) automatic drag roller deviation adjustment: when the conveyor belt deviation range is not large, a self-aligning drag roller can be installed at the conveyor belt deviation. (2) Appropriate tension and deflection adjustment: when losing

2018-05-17

17

2018-05

Driving and Braking System of Large Belt Conveyor

For the failure of the hydraulic system of on-site construction machinery, according to the working principle of the hydraulic system and the sequence of the power components-control components, the cause of the failure can be analyzed forward on the system diagram. For example, the working weakness of the excavator boom is considered to be caused by the decrease of oil pressure or flow rate. From the system diagram, the possible factors causing the pressure drop are: ① oil tank, such as lack of oil, the oil suction filter is blocked and the vent hole is not smooth; ② the hydraulic pump leaks, such as the increase of the matching clearance of the hydraulic pump plunger pair; ③ the pressure adjustment of the main safety valve on the control valve is too low, and the configuration of 30 is analyzed, and the relevant problems are carried out

2018-05-17

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-13915232058 86-15061750668

E-mail: sales@hdconveyor.com

Official Website