Cases of 1. borrowing

The most difficult part of the renovation project is to find the foothold of the outrigger of the pipe belt conveyor after the route is determined, which can be described as a stitch.

If it is really impossible to do the foundation on the ground, you can consider using the existing plant roof, the existing belt gallery support, pipe gallery support, transfer station, etc., but to borrow these structures to do the pipe belt machine support point, generally need to carry out structural accounting of its force load. Many old buildings because of the long time, the owner generally can not provide the structure and foundation construction drawings of the building, the force accounting will be very different, in this case need accounting can not borrow as far as possible.

Borrowed powerhouse column

The above picture borrows the two pillars of the existing iron powder storage yard factory building, because both sides of the factory building are passable roads, and the ditches on the side of the road are not allowed to be occupied. The two-legged steel column support is made on the top of the factory building column, and the structural calculation is carried out separately. At the same time, the steel column is added from the roof. The construction is relatively troublesome. The top of the factory building column should be cleaned first, and the rainproof measures of the roof should also be considered.

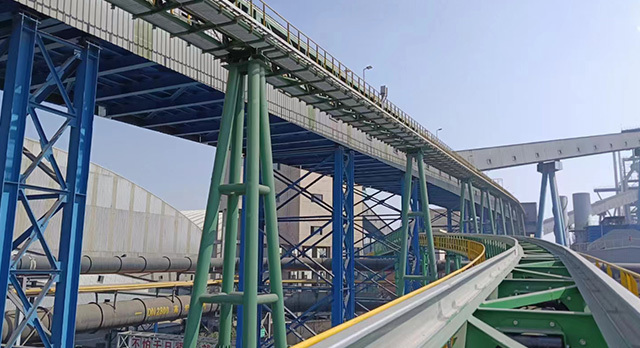

Borrowing dust suppression net column

The above figure borrows the pillars of the wind and dust suppression net, because one side of the dust suppression net is a road, and the other side is a retaining wall and a road. Traffic and beauty should be considered, and foundation pillars are allowed to be erected on the side of the road. Taking into account the force of the cantilever, additional reinforcement support was made in the follow-up.

Borrowing transfer station beam

The above picture borrows the transfer station of the existing belt corridor, because the belt conveyor on the same floor is obsolete and can be used. This force is no problem, and the space position to pass through is mainly considered. The total length of this pipe belt conveyor is about 1 kilometer, and the average overhead height is about 18 meters. The original design only has openings for upper and lower equipment at the head and tail transfer stations. The owner feels it is very inconvenient to check and repair. Therefore, it is close to the head 1/4 of the total length. Borrowing the transfer station has another advantage, adding a passage for the upper and lower pipe belt conveyors. Later, according to this convenience, the owner built a new inclined ladder to the aisle of the pipe belt conveyor at a transfer station close to the pipe belt conveyor at 1/4 of the total length of the tail of the pipe belt conveyor, thus adding an access port for the upper and lower pipe belt conveyors.

Borrowing transfer station column

In the above figure, the pipe belt conveyor passes between the two concrete transfer stations. The original design is to lay a foundation vertical support in the gap between the transfer stations. The owner considers to reduce the cost of civil engineering, and suggests that it is better to directly hold the transfer station column and build a bull leg to support it.

Borrowing pipe column

The above picture borrows the pipe column, and the gantry support is added directly above the existing column. The ground is a passage and the foundation is not allowed.

2. not borrowed cases

Add large span truss

In the above picture, the long-span trestle bridge is nearly 50 meters in span. In this area, there are inclined rubble slope protection with a height difference of nearly 10 meters on the ground, staggered belt corridors and pipelines in the air, and a simple brick wall flat roof house. The original design is that there is no such large-span truss. The preliminary plan is to borrow the existing flat roof house and build a structural frame on its roof. The structural frame focuses on the wall surface of the flat roof house, and then build a column to support the pipe belt conveyor on the structural frame. The owner of the latter plan denied it, mainly because he was afraid that the flat roof house could not bear this force (the house could not be demolished either).

The picture above is the photo before hoisting of large span truss.

Without the support point of the flat roof house, only the large span truss can be used. The large span truss is also difficult to hoist due to the limited construction space on site. After several hoisting schemes were designed and evaluated for many times, a 300-ton crane was finally called.

Increase the difficulty of column installation

In some places, if the existing buildings cannot be borrowed and it is not convenient to make large steel structure corridors, the need to add truss columns cannot be avoided at this time. The following figure shows two transfer stations. The load of the pipe belt conveyor was not taken into account in the structural design of the transfer station. The design institute did not agree that the truss fell directly on the beam of the transfer station, so it had to add a column inside the transfer station, causing the biggest problem. It was more troublesome to hoist the pipe belt conveyor structure in time.

The following figure cannot use the belt conveyor corridor as a support, but can only build columns in the only space between the intricate pipes and the corridor. The upright post cannot be erected to the top, and the space and foundation are limited. It can only be made into a small upper structure at the lower part, and the upper part holds the belt conveyor corridor. The height of the whole column is 21 meters. The biggest trouble of this design lies in hoisting and welding. The bottom four-legged column is not disconnected on site. As a whole, how to haul it in and install it in place should be careful to touch the surrounding gas pipelines. The columns are split and hoisted on site, and then assembled and welded at high altitude. The installation of this column takes the longest time.

3. Summary

Through the above multiple case studies to summarize two points:

1. If the force of the existing building structure allows, it can be borrowed as much as possible. This has two main advantages: one is to save space, especially for plant renovation projects; The second is to save the investment cost of civil construction foundation and equipment.

2. Under the condition that the existing buildings cannot be borrowed, the new foundation of the pipe belt conveyor should avoid the existing building foundation as much as possible to ensure that the two foundations do not interfere, so that the force will not be affected.

Other experience summary:

1. For the long-distance pipe belt conveyor of more than 1km, the transfer station that can be borrowed in the middle can be used as the upper and lower passage;

2. For places close to the house and buildings, the center of the support column foot of the pipe belt conveyor shall be at least 1.5m away from the edge of the wall of the house and buildings. When it can be taken, it shall be as large as possible, because it is better not to interfere with the foundation bearing platform of the house and the foundation bearing platform of the pipe belt conveyor.

3. Close to the belt gallery bracket and pipe bracket, the distance between the center of the support column foot of the pipe belt conveyor and the center of the original bracket is at least 1m, which can be as large as possible.

4. If it is impossible to avoid the need to be close to the design foundation such as buildings, special treatment is required during the foundation design.