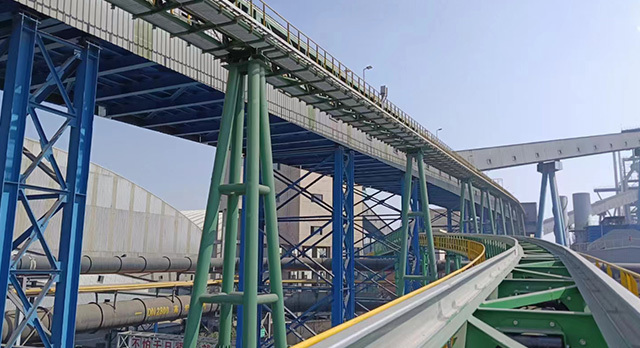

Analysis on Prevention and Treatment of Conveyor Belt Deviation

Release time:

May 17,2018

Conveyor belt deviation is a fault often encountered in the process of conveyor use, and it is also a headache for customers. How to prevent and eliminate the fault of the conveyor belt deviation? First check the cause, and then one by one "the right medicine". Preventive measures to 1. the deviation of the conveyor belt (1) improve the installation quality (2) improve the quality of the conveyor belt joint;(3) strengthen the inspection and maintenance of the tour (4) to ensure that the loading is not biased;(5) to ensure that the cleaning device is normal. On-site treatment method for 2. conveyor belt deviation (1) automatic drag roller deviation adjustment: when the conveyor belt deviation range is not large, a self-aligning drag roller can be installed at the conveyor belt deviation. (2) Appropriate tension and deflection adjustment: when losing

Conveyor belt deviation is a fault often encountered in the process of conveyor use, and it is also a headache for customers. How to prevent and eliminate the fault of the conveyor belt deviation? First check the cause, and then one by one "the right medicine". Preventive measures to 1. the deviation of the conveyor belt (1) improve the installation quality (2) improve the quality of the conveyor belt joint;(3) strengthen the inspection and maintenance of the tour (4) to ensure that the loading is not biased;(5) to ensure that the cleaning device is normal. On-site treatment method for 2. conveyor belt deviation (1) automatic drag roller deviation adjustment: when the conveyor belt deviation range is not large, a self-aligning drag roller can be installed at the conveyor belt deviation. (2) proper tightening and deviation adjustment: when the conveyor belt deviates from left to right and the direction is irregular, the conveyor belt is too loose, and the tensioning device can be properly adjusted to eliminate deviation. (3) Unilateral vertical roller deflection adjustment: the conveyor belt always deviates to one side, and several vertical rollers can be installed within the scope to reset the tape. (4) Adjust the deviation of the roller: check whether the conveyor belt deviates at the roller, check whether the roller is abnormal or moving, adjust the roller to the horizontal position to rotate normally to eliminate the deviation,(5) correct the deviation of the conveyor belt joint; The deviation of the conveyor belt is always in one direction, and the maximum deviation is at the joint. The deviation of the conveyor belt joint and the center line of the conveyor belt can be corrected to eliminate the deviation. (6), several groups of trailing rollers can be raised on the opposite side of the deviation direction to eliminate deviation. (7) Adjust the deviation of the drag roller: the deviation direction of the conveyor belt is certain. If it is found that the center line of the drag roller is not perpendicular to the center line of the conveyor belt, the drag roller can be adjusted to eliminate the deviation. (8) Eliminate the adjustment of appendages: the deviation point of the conveyor belt will not change. If appendages are found to be adhered to the drag roller and roller, the deviation shall be eliminated after removal. (9) Correction of feeding deviation: the belt is not biased under light load and deviates under heavy load. The feeding weight and position can be adjusted to eliminate deviation. (10) Correction of bracket deviation: The horizontal and vertical degree of the bracket can be adjusted to eliminate deviation in the direction of conveyor belt deviation, fixed position and serious deviation.

Key words:

Previous Page

Previous Page:

Recommended News

HUADONG Machinery

Add: No.8, Yanghuan Road, High-tech zone, Jiangyin, Jiangsu, China

Tel: 86-510-86195578

Mobile: 86-15190313883 86-18762809313

E-mail: sales@hdconveyor.com

Official Website